Berlatarbelakangkan kemajuan pesat industri kenderaan tenaga baharu, sektor pembuatan bateri litium memasuki tempoh tetingkap kritikal untuk inovasi teknologi dan globalisasi. Menurut data terkini daripada Persatuan Pengilang Automobil China, pada suku pertama 2025, pengeluaran dan jualan kenderaan tenaga baharu China masing-masing mencecah 3.182 juta dan 3.075 juta unit, mewakili peningkatan ketara tahun ke tahun sebanyak 50.4% dan 47.1%, memacu secara langsung lonjakan permintaan litium yang berterusan. Menghadapi gelombang peningkatan industri, Lenze, peneraju global dalam teknologi automasi, memanfaatkan inovasi teknologi mendalam dan strategi penyetempatan untuk membantu perusahaan bateri litium China mengatasi kesesakan kecekapan dan mempercepatkan perjalanan globalisasi mereka.

Kejayaan Teknologi: Penyelesaian Automasi Proses Penuh Membentuk Semula Logik Pengeluaran Bateri Litium

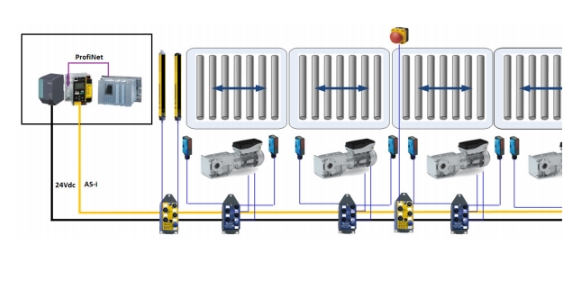

Dalam segmen teras pembuatan bateri litium, Lenze telah membina ekosistem automasi lengkap yang merangkumi daripada pemprosesan bahan mentah kepada logistik dan pengangkutan. Sistem pemacu penjimatan tenaga berprestasi tinggi yang baru dilancarkan, yang terdiri daripada motor m550/m650, pengurang g500 dan penyongsang i550/i650, telah menjadi tumpuan dalam industri. Dengan menggunakan teknologi segerak magnet kekal, sistem ini mencapai peningkatan kecekapan tenaga yang ketara. Dalam ujian barisan pengeluaran yang dijalankan oleh pengeluar bateri terkemuka, ia mengurangkan penggunaan tenaga sebanyak lebih 20% dan meningkatkan kestabilan operasi peralatan sebanyak 35%, dengan ketara mengoptimumkan jumlah kos kitaran hayat.

Untuk proses ketepatan seperti pembuatan elektrod, teknologi kawalan gerakan segerak Lenze mencapai ketepatan tahap nanometer. Dalam prosedur seperti salutan dan penggulungan pengumpul semasa, penyelesaiannya telah membantu pelanggan dalam mengawal sisihan ketebalan bahan dalam ±1μm, sambil meningkatkan ketumpatan tenaga bateri sebanyak 8%-12%. Pengarah teknikal dari perusahaan bateri kuasa menyatakan, "Sistem kawalan gelung tertutup Lenze telah membolehkan barisan pengeluaran kami mencapai kadar hasil melebihi 95%, dengan pengurangan 18% dalam penggunaan tenaga seunit output."

Strategi Globalisasi: Pendekatan Setempat Mendalami Penembusan Pasaran Serantau

Sebagai tindak balas kepada Peraturan Bateri Kesatuan Eropah keperluan kebolehkesanan jejak karbon dan halangan tarif AS, Lenze memacu pengembangan global perusahaan China melalui dua fokus pada "teknologi dan pematuhan." Seni bina automasi terbukanya disepadukan dengan lancar dengan sistem pasport bateri, membolehkan pengumpulan masa nyata penggunaan tenaga pengeluaran dan data pelepasan karbon untuk memenuhi keperluan kawal selia EU menjelang 2027. Pada masa ini, Lenze telah menyelesaikan penyesuaian sistem dengan tiga pengeluar peralatan terkemuka China, dengan satu perusahaan penyimpanan tenaga mencapai 100% kebolehkesanan data jejak karbon untuk kilang-kilangnya di Eropah, yang berjaya melepasi pensijilan TÜV.

Di pasaran Eropah, Lenze bekerjasama dengan Northvolt Sweden, bahagian bateri Volkswagen dan perusahaan lain untuk meneroka proses pengeluaran besar-besaran bateri keadaan pepejal. Pengurang servo planet tindak balas rendahnya mencapai ketepatan putaran 0.01° dalam proses salutan elektrolit pepejal, meletakkan asas perindustrian untuk teknologi bateri generasi akan datang. Pada masa yang sama, Lenze sedang mempercepatkan usaha penyetempatannya di China dengan menubuhkan pusat R&D Asia-Pasifik di Suzhou, membangunkan mekanisme perkhidmatan "tindak balas pantas 48 jam" untuk pelanggan domestik, dan mengurangkan kitaran penghantaran sebanyak 40%.

Pemerkasaan Perindustrian: Membina Ekosistem Baharu untuk Pembuatan Pintar Hijau

"Persaingan dalam industri bateri litium telah beralih daripada pengembangan kapasiti kepada pertempuran untuk ketumpatan teknologi dan keupayaan penyepaduan sumber global," kata Presiden Lenze China pada forum industri baru-baru ini. Pada masa ini, Lenze telah menjalin kerjasama yang mendalam dengan perusahaan seperti CATL dan BYD, dengan sistem logistik pintarnya yang membolehkan penjadualan diselaraskan peringkat milisaat bagi lebih 2,000 AGV dalam kilang mega, kecekapan pergudangan tiga kali ganda.

Memandang ke hadapan, Lenze merancang untuk melabur €200 juta dalam tempoh tiga tahun dalam R&D untuk peralatan pengeluaran bateri keadaan pepejal dan akan melancarkan inisiatif "Kilang Rumah Api" di China, menggunakan teknologi kembar digital untuk melihat pratonton penyelesaian pengoptimuman barisan pengeluaran. Penganalisis industri percaya bahawa apabila industri bateri global memasuki fasa kemajuan teknologi yang mendalam, Lenze—dengan keupayaan penyelesaian proses penuh dan rangkaian perkhidmatan setempatnya—akan menjadi rakan kongsi penting bagi perusahaan bateri litium China dalam usaha pasaran global mereka.

Di persimpangan lelaran teknologi bateri kuasa dan penstrukturan semula industri, Lenze menyuntik kepastian ke dalam pembuatan pintar bateri litium melalui gabungan "kecemerlangan kejuruteraan Jerman dan kelajuan China." Daripada peralatan kendiri kepada kilang digital, dan daripada penemuan tempatan kepada global布局, transformasi yang dipacu oleh teknologi automasi sedang berlaku.