Pendawaian Kabinet Kawalan Tradisional Menghadapi Dua Cabaran Kecekapan dan Kemampanan

Dalam bidang automasi perindustrian, pendawaian kabinet kawalan tradisional telah lama bergantung pada berkas kabel yang kompleks untuk menyambungkan pemula motor, penderia, pemutus litar dan komponen lain. Pendawaian manual bukan sahaja memakan masa yang ketara (memerlukan lebih 20 jam untuk memasang kabinet kawalan tunggal) tetapi juga terdedah kepada ralat seperti sambungan yang salah, label tidak sepadan dan sambungan terlepas, yang membawa kepada kerja semula dan pembaziran bahan. Memandangkan peralihan pembuatan global ke arah pengeluaran risikan dan hijau, memudahkan proses pendawaian dan mengurangkan penggunaan sumber telah menjadi permintaan industri yang mendesak.

Automasi Rockwell Melancarkan Sistem Ethernet/IP Dalam Kabinet ALLEN BRADLEY, Meningkatkan Kecekapan Pendawaian sebanyak 80%

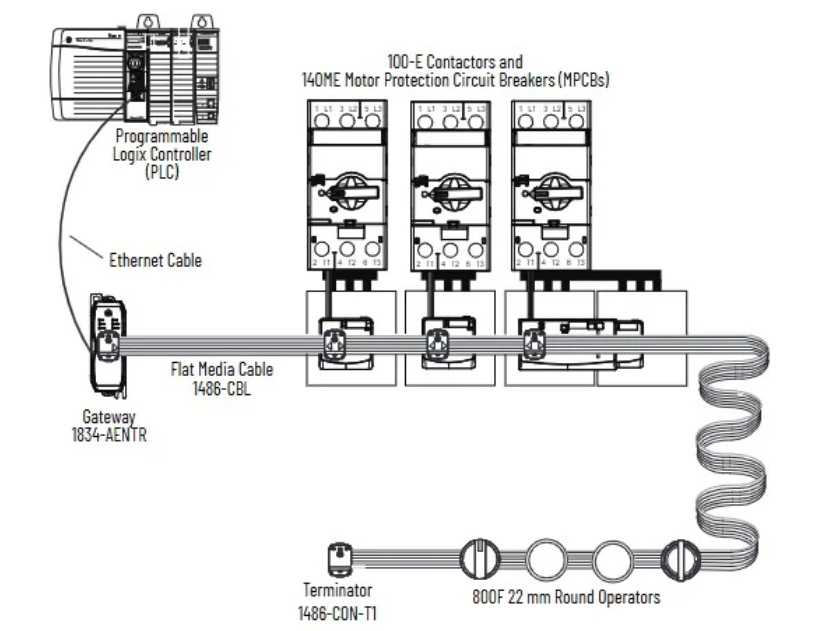

Rockwell Automation (NYSE: ROK), peneraju global dalam automasi industri, baru-baru ini memperkenalkan penyelesaian inovatif di bawah jenama Allen-Bradleynya: sistem Ethernet/IP Dalam Kabinet. Dengan menggantikan pendawaian keras tradisional dengan sepasang kabel Ethernet tunggal, sistem ini membolehkan bekalan kuasa rangkaian dan komunikasi merentas semua peranti, mengurangkan masa pendawaian sebanyak lebih 80% dan mengurangkan penggunaan tembaga dan plastik dengan ketara.

Ujian dunia sebenar oleh rakan kongsi Brazil Volga mendedahkan bahawa masa pemasangan kabinet kawalan menurun daripada 20 jam kepada di bawah 7 jam selepas menerima pakai sistem, menandakan peningkatan kecekapan sebanyak 66%. Pengarah Komersial Volga Carlos Leopoldo memuji kebolehgunaan dan kebolehpercayaan sambungannya, dengan menyatakan, "Pasukan melaporkan ia sangat mudah digunakan dan jauh melebihi jangkaan dalam kestabilan."

Seni Bina Modular Membentuk Semula Paradigma Ketersambungan Industri, Memajukan Kemampanan Kitaran Hayat Penuh

Penyelesaian Rockwell melangkaui kecekapan pemasangan, menggunakan kabel media rata 7 teras untuk mencipta seni bina rangkaian tulang belakang berskala. Reka bentuk ini mengurangkan volum kabinet kawalan sebanyak 36% dan berat sebanyak 32%, secara langsung mengurangkan penggunaan bahan dalam pembuatan dan pengangkutan. Sifat modularnya menyokong peningkatan berulang atas permintaan, mengelakkan baik pulih sistem warisan yang mahal dan membenamkan prinsip pembuatan hijau merentas keseluruhan kitaran hayat—daripada reka bentuk hingga persaraan.

Sebagai penanda aras untuk menyepadukan automasi industri dan teknologi maklumat, Rockwell Automation (pemilik jenama utama seperti Allen-Bradley dan FactoryTalk) mengesahkan semula kepimpinan teknologinya dengan kejayaan ini. Syarikat itu berkhidmat kepada lebih 20 industri, termasuk automotif dan sains hayat, menawarkan penyelesaian hujung ke hujung merangkumi PLC (cth, AB MicroLogix 1500), pemacu (siri AB PowerFlex 7000), dan perisian. Pelancaran sistem dalam kabinet Ethernet/IP menandakan peralihan penting daripada "perkakasan mekanikal" kepada "nod rangkaian pintar" dalam ketersambungan peralatan industri, menyediakan infrastruktur kritikal untuk pembangunan kilang pintar.

Pengarah Pemasaran Global Rockwell Automation mengulas, "Teknologi ini lebih daripada alat kecekapan—ia merupakan asas kepada sambungan Industri 4.0. Melalui protokol piawai dan reka bentuk dipacu data, peranti akan mencapai pengoptimuman kendiri dan kerjasama merentas domain." Memandangkan jenama Allen-Bradley terus memacu transformasi digital dalam pembuatan, lonjakan pintar kabinet kawalan mencerminkan evolusi industri global yang lebih luas.