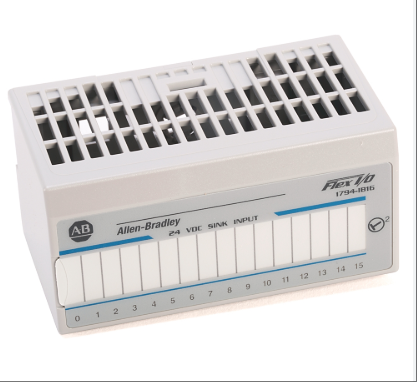

Allen Bradley 1794-IE8B/A ialah modul input analog berprestasi tinggi dalam sistem Flex I/O di bawah Automasi Rockwell, direka khusus untuk senario automasi industri. Sebagai komponen teras siri produk Flex I/O, modul ini mencapai pemerolehan ketepatan tinggi bagi isyarat voltan/arus melalui 8 saluran tunggal, tidak terpencil, boleh dikonfigurasikan pengguna, dan digunakan secara meluas dalam bidang seperti kawalan proses, pemantauan peralatan dan pemerolehan data.

1、 Penjelasan terperinci tentang parameter teras

● Saluran input dan julat isyarat

Konfigurasi saluran: 8 saluran input hujung tunggal, menyokong akses bercampur bagi isyarat voltan dan arus.

Jenis isyarat:

Input semasa: 0-20mA, 4-20mA (isyarat standard industri, sesuai untuk output sensor).

Input voltan: ± 10VDC, 0-10VDC (serasi dengan pelbagai isyarat kawalan proses).

● Resolusi dan ketepatan

kuasa penyelesaian:

Mod unipolar: 12 bit (1/4096 resolusi skala penuh).

Mod bipolar: 11 bit+bit tanda (1/2048 resolusi skala penuh).

Indeks ketepatan:

Pada 25 ℃: ± 0.20% julat penuh (voltan/input semasa).

Pada 0 ℃: ± 0.25% julat penuh (input voltan), ± 0.20% julat penuh (input semasa).

Hanyutan suhu: Input voltan ≤ 0.00428%/℃, input semasa ≤ 0.00407%/℃.

● Kadar penukaran dan masa tindak balas

Kadar penukaran: 256 μ s/saluran (keupayaan pensampelan berkelajuan tinggi).

Tindak balas langkah:

Terminal voltan: 9.4ms (63% tindak balas langkah).

Terminal semasa: 18.2ms (63% tindak balas langkah).

● Bekalan kuasa dan penggunaan kuasa

Voltan bekalan kuasa: 10.5-31.2VDC (nominal 24VDC), serasi dengan piawaian bekalan kuasa tapak industri.

Penggunaan semasa: 60mA (penggunaan kuasa maksimum 3W), pelesapan haba 10.2BTU/jam (pada 31.2VDC).

● Kebolehsuaian alam sekitar

Suhu kerja: -20 hingga 55 ℃ (beberapa senario boleh mencapai -20 hingga 60 ℃).

Suhu penyimpanan: -40 hingga 85 ℃ (sesuai untuk penyimpanan alam sekitar yang melampau).

Julat kelembapan: 5% -95% (keadaan tidak terkondensasi).

Kekuatan mekanikal:

Getaran: 5g (10-500Hz).

Kesan: 30g dalam keadaan bekerja, 50g dalam keadaan tidak berfungsi.

2、 Ciri fizikal dan pemasangan

● Struktur mekanikal

Saiz: 3.7 x 2.1 x 31.8 inci (reka bentuk padat, menjimatkan ruang pemasangan).

Kaedah pemasangan: Menyokong pemasangan rel DIN atau pemasangan panel, serasi dengan pelbagai kabinet industri.

Pangkalan serasi: 1794-TB2, 1794-TB3, 1794-TB3S, 1794-TB3T, 1794-TB3TS, dsb.

● Antara muka dan lampu penunjuk

Antara muka input: Pendawaian asas terminal, menyokong kabel terlindung untuk mengurangkan gangguan elektromagnet.

Penunjuk status: Lampu penunjuk kuasa (hijau) dan lampu penunjuk saluran (kuning, 8 saluran dipaparkan secara berasingan).

3、 Kelebihan prestasi dan senario aplikasi

● Kelebihan prestasi

Pemerolehan ketepatan tinggi: resolusi 12 bit dan drift suhu rendah memastikan ketepatan data.

Julat isyarat yang luas: serasi dengan isyarat arus/voltan industri yang biasa digunakan, mengurangkan langkah penyaman isyarat.

Respons pantas: Kadar penukaran 256 μ s/saluran memenuhi keperluan kawalan kelajuan tinggi.

Tahan lama dan kukuh: Tahap perlindungan IP20, sesuai untuk persekitaran industri yang keras.

● Senario aplikasi biasa

Kawalan proses: Pemantauan aliran, tekanan dan suhu dalam industri seperti kejuruteraan kimia dan rawatan air.

Pemantauan peralatan: Mengumpul isyarat maklum balas tentang kelajuan motor, ketegangan dan kedudukan pada barisan pengeluaran.

Pengumpulan data: Membaca data daripada meter elektrik dan gas dalam Sistem Pengurusan Tenaga (EMS).

Modul input analog Allen Bradley 1794-IE8B/A, dengan keupayaan pemerolehan ketepatan tinggi 8 saluran, julat isyarat yang luas dan kebolehsuaian alam sekitar gred industri, telah menjadi penyelesaian pilihan dalam bidang automasi industri. Sama ada industri proses yang memerlukan kawalan tepat atau senario pembuatan diskret yang memerlukan data masa nyata yang tinggi, modul ini boleh menyediakan sokongan input isyarat yang stabil dan boleh dipercayai, membantu perusahaan mencapai pengurusan pengeluaran yang cekap dan pintar.